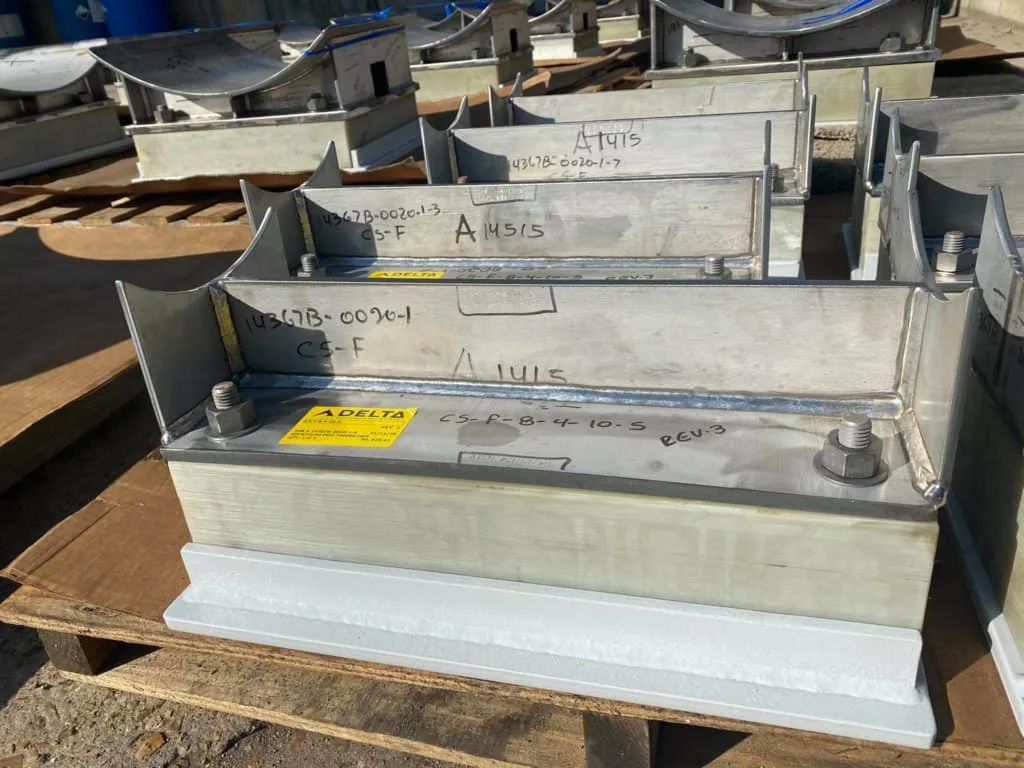

Pipe Shoes / Saddle Shoes

- Split Tee Shoe / Tee Sliders

- Pipe/Tank/Vessel Cradles

- Cold Shoes

Designed to support over-sized and heavyweight piping, pipe shoes (also referred to as pipe line shoes or piping shoes) elevate the pipe at some height above the supporting foundation or structure. Pipe shoes sometimes act as a wear plate for process piping to prevent wall thinning from vibration or thermal cycles. Generally pipe shoes are custom made with a fast turnaround to meet specific project requirements.

Pipe Shoes / Saddle Shoes FAQs

You should size your saddle pipeline shoe based on the diameter of the pipe and the thickness of the insulation.

An anchor system can be used to keep the pipe in position, with supportive structures incorporated into the design to maintain constant tension throughout the pipe’s operating cycle.

Always ensure that your pipe shoes lack severe corrosion or damage to the shoe plate components. Additionally, verify the following for these shoe types:

- Welded design pipe shoes — welds are intact.

- Bolted pipe shoes — bolts are intact, all components are tightened to the correct torque specifications.

- Insulated supports — bolts are intact and properly tightened, insulation is complete without being damaged or exposed to the environment.

A hot shoe is a type of insulated pipe shoe / support that cradles the pipe, and is intended to withstand extremely high temperatures of over 200 degrees Fahrenheit.

A Split-T is a pipe shoe made from a cut W-beam. The flange becomes the base of the shoe and the web section is welded to the pipe.

Case Studies

Supporting a Massive Ethylene Plant Expansion

- 395 Tons of Steel Consumed

- 99% On-Time Shipments

- 60k Shop Hours Worked